July 27, 2007

Three people were killed and another three seriously injured in a blast at Mojave Spaceport, located in California, United States. The blast occurred on Thursday at 2:34 p.m. PDT (UTC-7) while Scaled Composites was conducting cold flow test of a rocket engine.

According to Tony Diffenbaugh of the Kern County Fire Department, two of the victims died immediately in the blast, while the third succumbed to his injuries at the hospital.

"Our units arrived on the scene at a remote test site in the northeast portion of the airport. What they found was six victims of an apparent explosion with various traumatic and burn injuries," Diffenbaugh said.

Burt Rutan, founder of Scaled Composites, said a press conference: "We just don't know" why the explosion occurred, nitrous oxide usually is "not considered a hazardous material."

Scaled Composites is in a partnership with Richard Branson's Virgin Galactic to build SpaceShipTwo, which hopes to become the first commercially available passenger spaceflight for space tourism.

The accident comes just days after Northrop Grumman announced it would increase its stake in Scaled Composites to 100%.

>> Elon Musks's SpaceX project aims to put objects in orbit with more standard liquid oxygen rockets, much more difficult than the 100 sub-orbit that defines 'space'. Unfortunately its second flight failed to reach orbit because of control issues:

Second test flight of Falcon 1

The second Falcon 1 launched a demonstration payload to return data on the booster's performance, however it failed to reach orbit. The second stage was shut down about a minute and a half before schedule (T+ 7:30) due to a control issue. [4] SpaceX later stated that "The second stage was otherwise functioning well and even deployed the satellite mass simulator ring at the end of flight! Actual final velocity was 5.1 km/s or 11,000 mph, whereas 7.5 km/s or 17,000 mph is needed for orbit."

The first launch attempt was targeted for 2300 UTC, 20 March 2007 however it was aborted one minute and two seconds prior to launch (T minus 00:01:02) due to a ground control software handover failure. A second attempt was made at 00:05 UTC, 21 March 2007, but the launch was aborted automatically 0.5 seconds after firing the engines because the main engine chamber pressure was about 0.2 percent lower than allowable. The low pressure was caused by the fuel being colder than desired. The third attempt successfully launched the rocket at 01:10 UTC, 21 March 2007 (13:10 local time, 20 March 2007), the vehicle separated from the first stage booster and fairing at approximately 6:14 PST.

The webcast from the vehicle was lost at T+ 5:05 at an altitude of approximately 300 kilometers, but SpaceX was able to retrieve telemetry for the entire mission. The video showed a coning motion that increased during the second stage burn, then a roll immediately before loss of signal.[5] Musk noted that the control problem was initiated during stage separation, when the shut down kick of the main engine exceeded their predictions. This caused a bump between the first stage and second stage engine nozzle, along with sloshing in the tanks. The vehicle's systems were designed to damp out sloshing, but the unexpected motion exceeded design parameters. [4]

SpaceX stated they were happy with the launch as the rocket reached space and validated the riskiest and most difficult parts of the new design. Musk expressed confidence that they would solve the control issue and noted that all new rockets typically have these problems to work out; "I think they had something like 12 Atlas failures before the 13th one was success. To get this far on our second launch being an all-new rocket -- new main engine, new first stage, new second stage engine, new second stage, new fairing, new launch pad system, with so many new things -- to have gotten this far is great." [6] A post-mission report declared this launch "the end of the test phase for Falcon 1 and the beginning of the operational phase." [7]

>>> Finally, it appears that early estimates that carbon nanotubes (a form of carbon stronger than diamond) are a candidate material for building a skyhook (see here) were overly optimistic. First, because the measured tensile strength of real nanotubes are about half of their theoretical limit; and second, because the impurities which cause this weakness are more or less inevitable.

In this paper various deterministic and statistical models, based on new quantized theories proposed by the author, are presented for estimating the strength of a real, and thus defective, space elevator cable. The cable, ~100 000 km in length, is composed of carbon nanotubes, ~100 nm long: thus, its design involves nanomechanics and megamechanics. The predicted strengths are extensively compared with the experimental and atomistic simulation results for carbon nanotubes available in the literature. All these approaches unequivocally suggest that the megacable strength will be reduced by a factor at least of ~70% with respect to the theoretical nanotube strength, today (erroneously) assumed in the cable design. The reason is the unavoidable presence of defects in so huge a cable. Preliminary in-silicon tensile experiments confirm the same finding. The deduced strength reduction is sufficient to place in doubt the effective realization of the space elevator, that if built as designed today will certainly break (in the author's opinion). The mechanics of the cable is also revised and possible damage sources discussed.>> For all that, the mass production of long nanotubes has grown by leaps and bounds and now exceeds the length extimated here by a factor of several million:

|

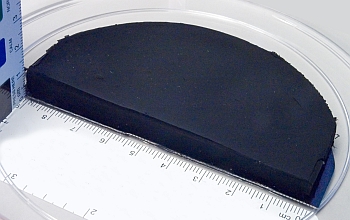

The carbon nanotubes grew atop a specially designed wafer catalyst that allowed growth to continue for a relatively long duration. The individual fibers are difficult to discern in this image but appear as striations when they catch the light. |